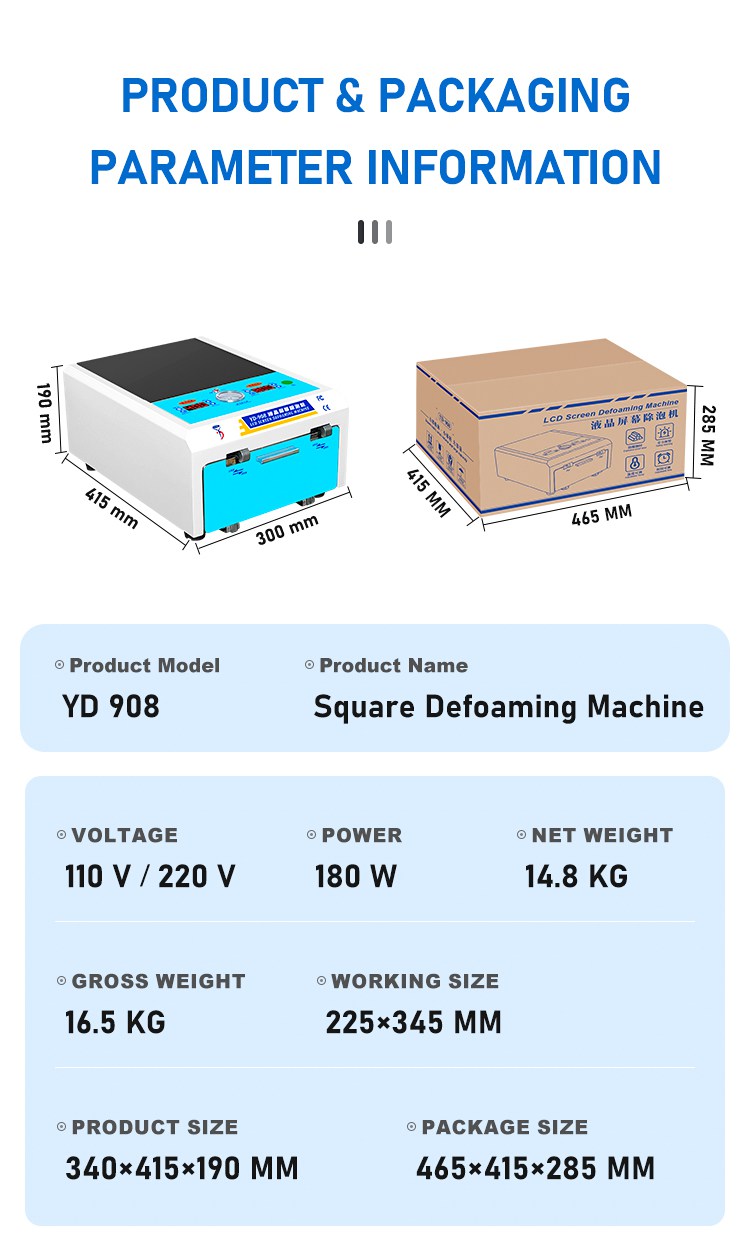

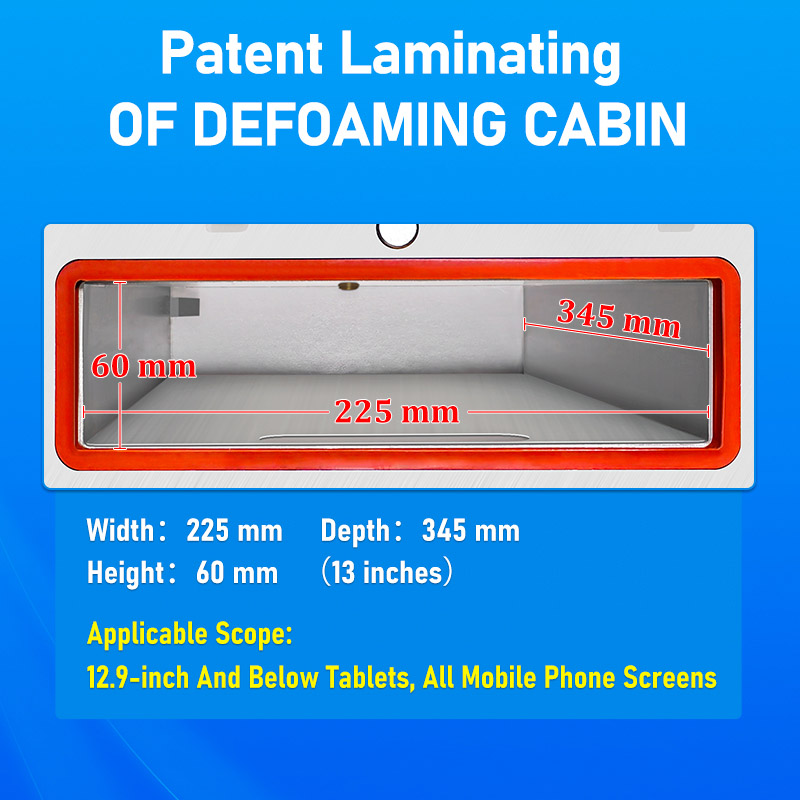

The Square High-Pressure Screen Defoamer is an essential piece of equipment for mobile phone and tablet repair shops, specifically designed to handle the delicate task of removing air bubbles and imperfections from laminated screens. With a 16-inch defoaming space, this machine can accommodate screens up to 12.9 inches in size, including large panel (LP) displays. Its compact design makes it ideal for repair technicians who need high efficiency in a smaller footprint, offering both powerful performance and a space-saving solution for any repair environment.

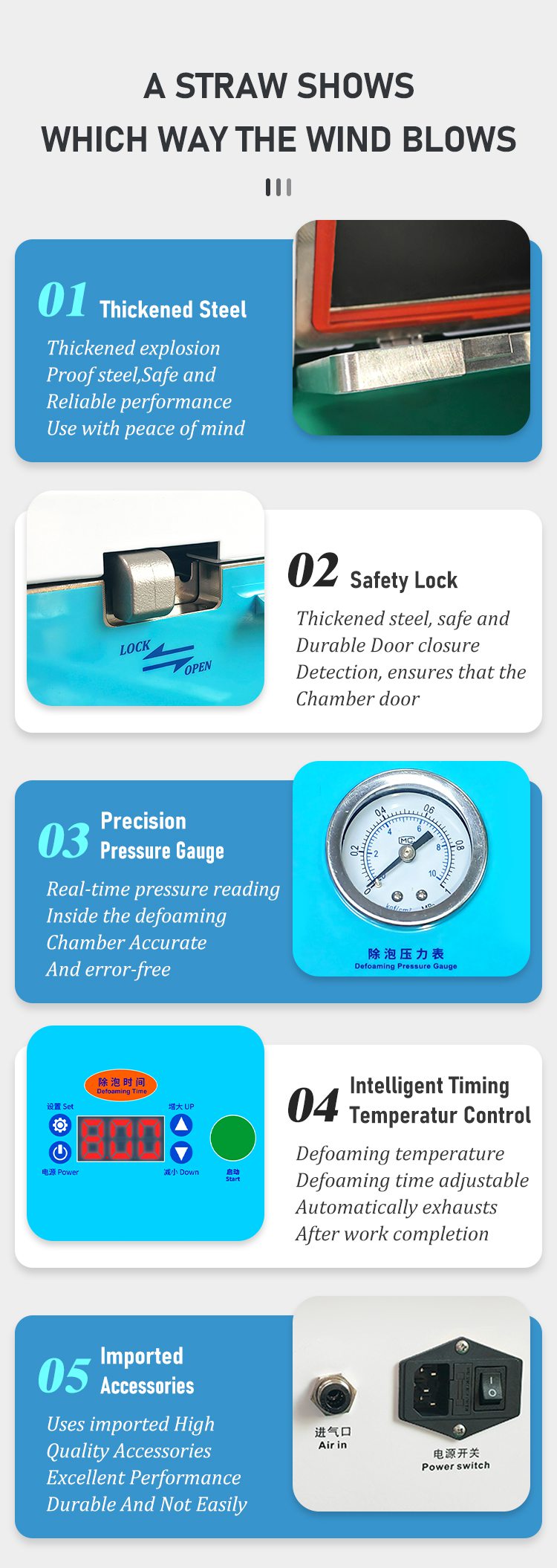

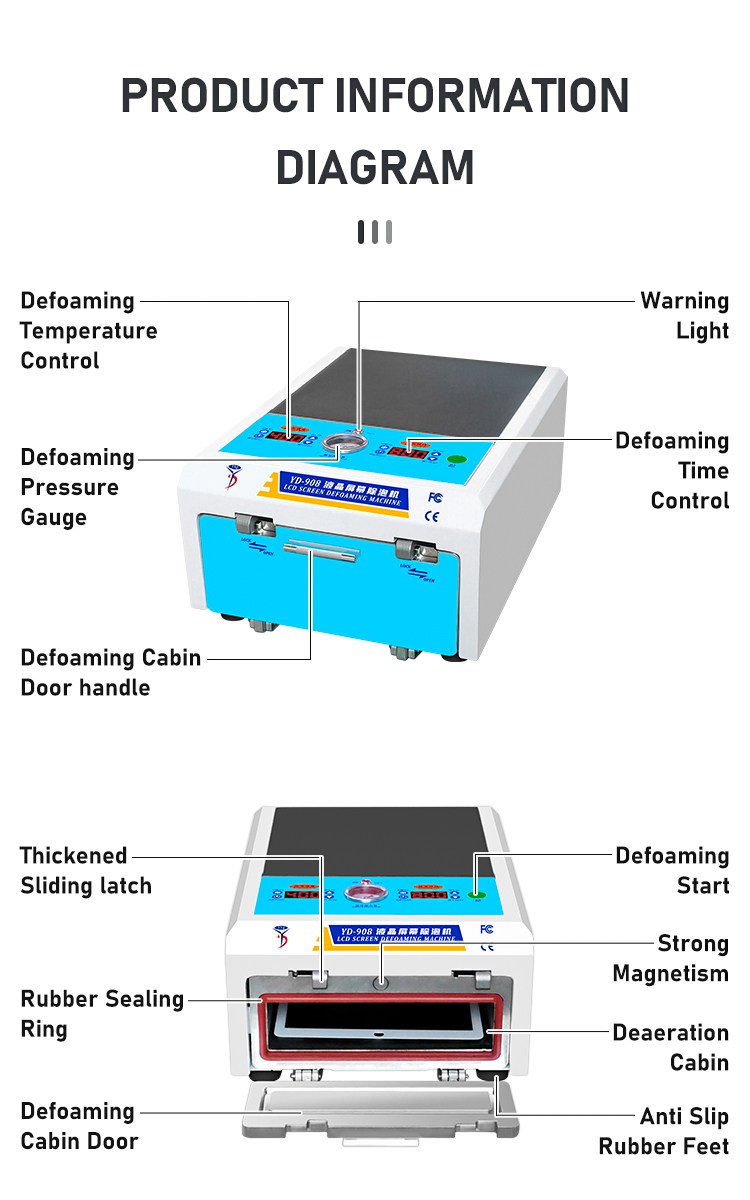

One of the key features of the square high-pressure screen defoamer is its durable and robust construction. The barrel body of the machine is made from thickened steel, which ensures the machine is built to last, even under continuous, high-pressure use. The material’s strength and reliability are vital for ensuring that the machine can withstand the demands of a busy repair shop, where frequent use is expected. Furthermore, the 304 stainless steel lock buckle and hinge add an additional layer of security, making the machine safe and explosion-proof, which is crucial when working with high-pressure equipment. The stainless steel components are resistant to rust and corrosion, ensuring the machine remains operational for years.

In addition to the robust build, the high gloss electroplating process applied to the machine not only provides an attractive finish but also ensures that the machine is resistant to wear and corrosion. This electroplating process improves the machine’s longevity, helping it maintain its pristine appearance even after extended periods of use. The electroplating process also contributes to its overall durability, which is especially beneficial in a fast-paced repair environment where the machine undergoes constant use.

Safety is a top priority with the square high-pressure screen defoamer. The machine is designed with an explosion-proof door function to further enhance safety. If the door is not securely locked, an automatic alarm will sound, and the machine will not enter the air pressure stage. This safety feature prevents any dangerous situations from occurring during the defoaming process, ensuring that technicians can focus on their work without worrying about the equipment malfunctioning. The warning system is a crucial element for reducing accidents and maintaining a safe working environment.

Once the alarm is triggered, the machine cannot proceed to its working state until the safety inspection has been completed. This self-inspection safety feature guarantees that the machine will only operate when it is fully secure, further reducing the risk of malfunctions or accidents. This level of safety makes the square high-pressure screen defoamer one of the most reliable and user-friendly options available for mobile phone and tablet screen repair professionals.

The square high-pressure screen defoamer is specifically designed for removing bubbles and imperfections that may occur during the lamination process of OLED, LCD, and other types of screens. It ensures that the screen is perfectly clear and free of any trapped air, which can degrade the visual quality of the display. Whether you are repairing smartphones, tablets, or other electronic devices, this machine is an invaluable tool in ensuring a high-quality, professional finish on every repair.

In conclusion, the square high-pressure screen defoamer combines advanced safety features, durable construction, and efficient defoaming capabilities into one compact, high-performance machine. Its thickened steel barrel, 304 stainless steel components, and explosion-proof design ensure that it is both reliable and safe to use. The high gloss electroplating and self-inspection safety features guarantee that the machine not only performs well but also maintains its functionality and appearance over time. For technicians and repair shops seeking a high-quality, reliable, and safe solution for screen defoaming, this machine offers the best of both performance and security.

Reviews

There are no reviews yet.